Casimir forces between infinite-area silicon slabs (2D periodicity)

In this example, we exploit scuff-em's

support for 2D periodic geometries

to compute the equilibrium Casimir force per unit area

between silicon slabs of infinite surface area.

The files for this example may be found in the

share/scuff-em/examples/SiliconSlabs subdirectory

of your scuff-em installation.

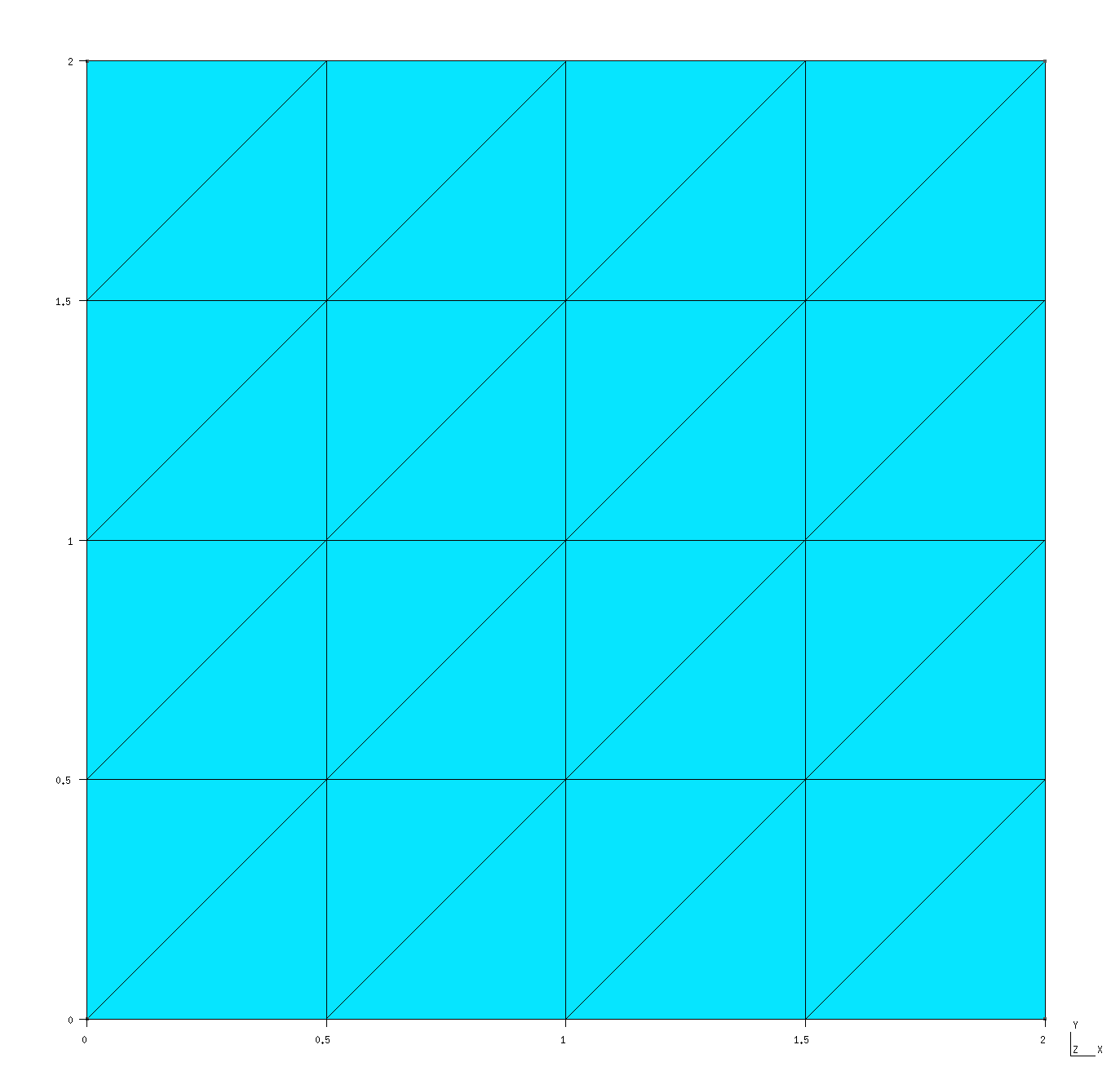

gmsh geometry file for unit-cell geometry

The gmsh geometry file Square_N.geo

describes the portion of the surface of a single

slab that lies within the unit cell,

i.e. the cell that is infinitely periodically

replicated to yield the full geometry.

In this case, the slab is infinitely thick (it is a

half-space), so its surface consists of just a single

two-dimensional sheet extending throughout the entire

unit cell. I call this file Square_N.geo to

remind myself that it contains a parameter N

that describes the meshing fineness; more specifically,

N defines the number of segments per unit length.

To produce a discretized surface-mesh representation of this geometry, we run it through gmsh:

% gmsh -2 Square_N.geo

This produces the file Square_N.msh, which

I rename to Square_L2.40.msh because the side length

of the square is and because

this particular mesh has 40 interior edges (this

number defines the number of surface-current basis

functions and thus the size of the BEM matrix in a

scuff-em calculation). Editing the .geo file

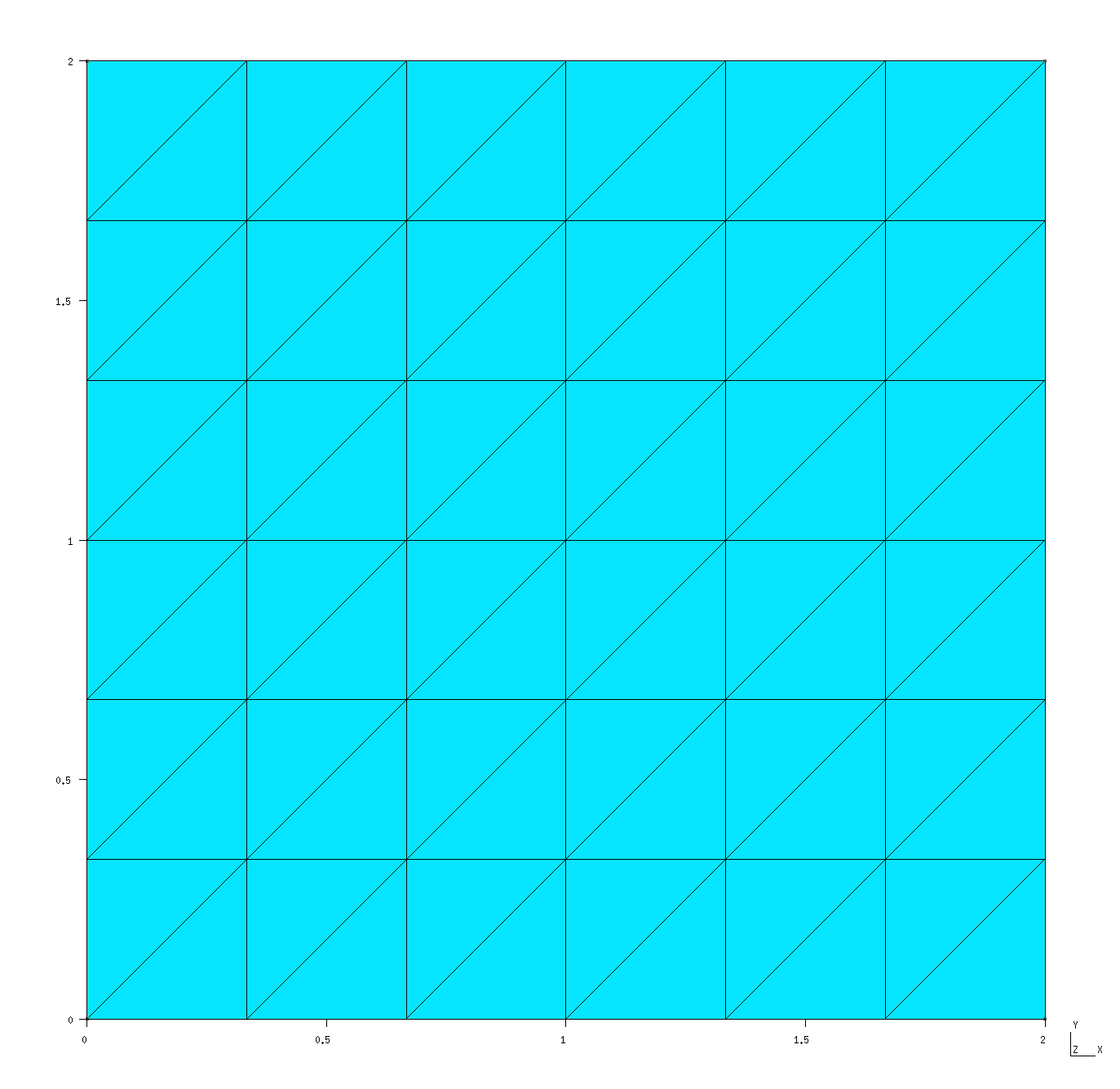

to change the N parameter to 3 (from its default

value of 2) and re-running gmsh -2 produces a

finer mesh file, which I rename to Square_L2_96.msh.

These meshes may be visualized in gmsh:

% gmsh Square_L2_40.msh % gmsh Square_L2_96.msh

Square_L2_40.msh

Square_L2_96.msh

Note the following:

-

For 2D periodic geometries in scuff-em, the lattice vectors must lie in the plane.

-

For surfaces that straddle the unit-cell boundaries (as is the case here), each triangle edge that lies on any edge of the unit cell must have an identical image edge on the opposite side of the unit cell. An easy way to achieve this is to use extrusions in gmsh, as in the

.geofile above. -

In this case the unit cell dimensions are where . (More generally, and may be any arbitrary nonzero values, and they need not equal each other.)

scuff-em geometry file

The

scuff-em geometry file

describing two silicon half-spaces (infinitely-thick slabs)

bounded by the coarser of the two unit-cell meshes described

above is SiliconSlabs_L2_40.scuffgeo:

# SCUFF-EM geometry file for two silicon slabs, # each of infinite cross-sectional area and infinite # thickness, separated in the z direction by 1 microns LATTICE VECTOR 2.0 0.0 VECTOR 0.0 2.0 ENDLATTICE MATERIAL SILICON epsf = 1.035; # \epsilon_infinity eps0 = 11.87; # \epsilon_0 wp = 6.6e15; # \plasmon frequency Eps(w) = epsf + (eps0-epsf)/(1-(w/wp)^2); ENDMATERIAL REGION UpperSlab MATERIAL Silicon REGION Gap MATERIAL Vacuum REGION LowerSlab MATERIAL Silicon SURFACE UpperSurface MESHFILE Square_L2_40.msh REGIONS UpperSlab Gap DISPLACED 0 0 0.5 ENDOBJECT SURFACE LowerSurface MESHFILE Square_L2_40.msh REGIONS LowerSlab Gap ENDOBJECT

Note the following points:

-

Even though our geometry doesn't contain any multi-material junctions, nonetheless we have to describe it using

REGIONandSURFACEstatements instead ofOBJECT...ENDOBJECTstatements because the geometry can't be described as one or more compact objects embedded in an exterior medium. -

In the default configuration described by the

.scuffgeofile, the slab surfaces are displaced from each other by a distance of 0.5 m. The geometric transformations described below will be relative to this default separation.

scuff-em transformation file

The file describing a list of

geometric transformations

is Slabs.trans:

TRANS 0.5 SURFACE UpperSurface DISP 0 0 0.0 TRANS 1.0 SURFACE UpperSurface DISP 0 0 0.5 TRANS 1.5 SURFACE UpperSurface DISP 0 0 1.0 TRANS 2.0 SURFACE UpperSurface DISP 0 0 1.5 TRANS 2.5 SURFACE UpperSurface DISP 0 0 2.0 TRANS 3.0 SURFACE UpperSurface DISP 0 0 2.5 TRANS 3.5 SURFACE UpperSurface DISP 0 0 3.0 TRANS 4.0 SURFACE UpperSurface DISP 0 0 3.5 TRANS 4.5 SURFACE UpperSurface DISP 0 0 4.0 TRANS 5.0 SURFACE UpperSurface DISP 0 0 4.5

It's convenient to visualize the effect of these transformations on our geometry before we run the calculation:

% scuff-analyze --geometry SiliconSlabs_L2_40.scuffgeo --TransFile Slabs.trans

This produces the file SiliconSlabs_L2_40.transformed.pp,

which can be visualized by opening it in GMSH:

![]()

Launching the run

Here's a bash script that will run the full Casimir

calculation on both the coarser and finer meshes:

# /bin/bash for N in 40 192 do ARGS="" ARGS="${ARGS} --geometry SiliconSlabs_L2_${N}.scuffgeo" ARGS="${ARGS} --TransFile Beams.trans" ARGS="${ARGS} --BZSymmetry BZSymmetry" ARGS="${ARGS} --energy" ARGS="${ARGS} --zForce" scuff-cas3D ${ARGS} done

This produces the files SiliconSlabs_L2_40.out

and SiliconSlabs_L2_96.out. The former file looks

like this:

# scuff-cas3D run on superhr1 at 06/15/15::23:50:32 # data file columns: #1: transform tag #2: energy #3: energy error due to numerical Xi integration #4: z-force #5: z-force error due to numerical Xi integration 0.5 -1.254502e-01 5.463886e-05 -7.264755e-01 3.268714e-04 1.0 -1.631064e-02 5.770642e-06 -4.865678e-02 2.055737e-05 ...

Now plot the energy and force per unit area vs. separation distance:

% gnuplot gnuplot> set xlabel 'surface--surface separation (um)' gnuplot> set ylabel 'Energy / (\hbar c / 1um), Force / ( \hbar c/(1um^2) )' gnuplot> set logscale y gnuplot> FILE='SiliconSlabs_L2_N40.out' gnuplot> plot FILE u 1:2 t 'Energy (SCUFF)', '' u 1:4 t 'Force (SCUFF)'

![]()

In this plot, the solid lines are the results of the Lifshitz formula for the Casimir energy and force between silicon slabs.